Bath University researchers testing new made-to-measure liners for prosthetics

- 26.06.2019

- JessicaMG

- Personal-injury, Personal-injury, Personal-injury, Personal-injury

John Roberts says he is ‘happy to be a guinea pig’ if it means helping others.

The 70-year-old was born prematurely, with one leg shorter than the other. Throughout his life, John tried various correctional shoes and boots, calipers and even underwent an operation to relieve the pain he experienced daily. Yet nothing worked.

In a last resort attempt, John recently had his lower leg amputated – a decision which he claims has greatly improved his quality of life. John now faces, along with approximately 45,000 others in England, a long recovery process – which includes getting used to his prosthetic.

Following an amputation, the size and shape of the stump may change, which often leads to pain and discomfort - particularly when wearing a prosthetic - resulting in some amputees favouring the use of a wheelchair instead.

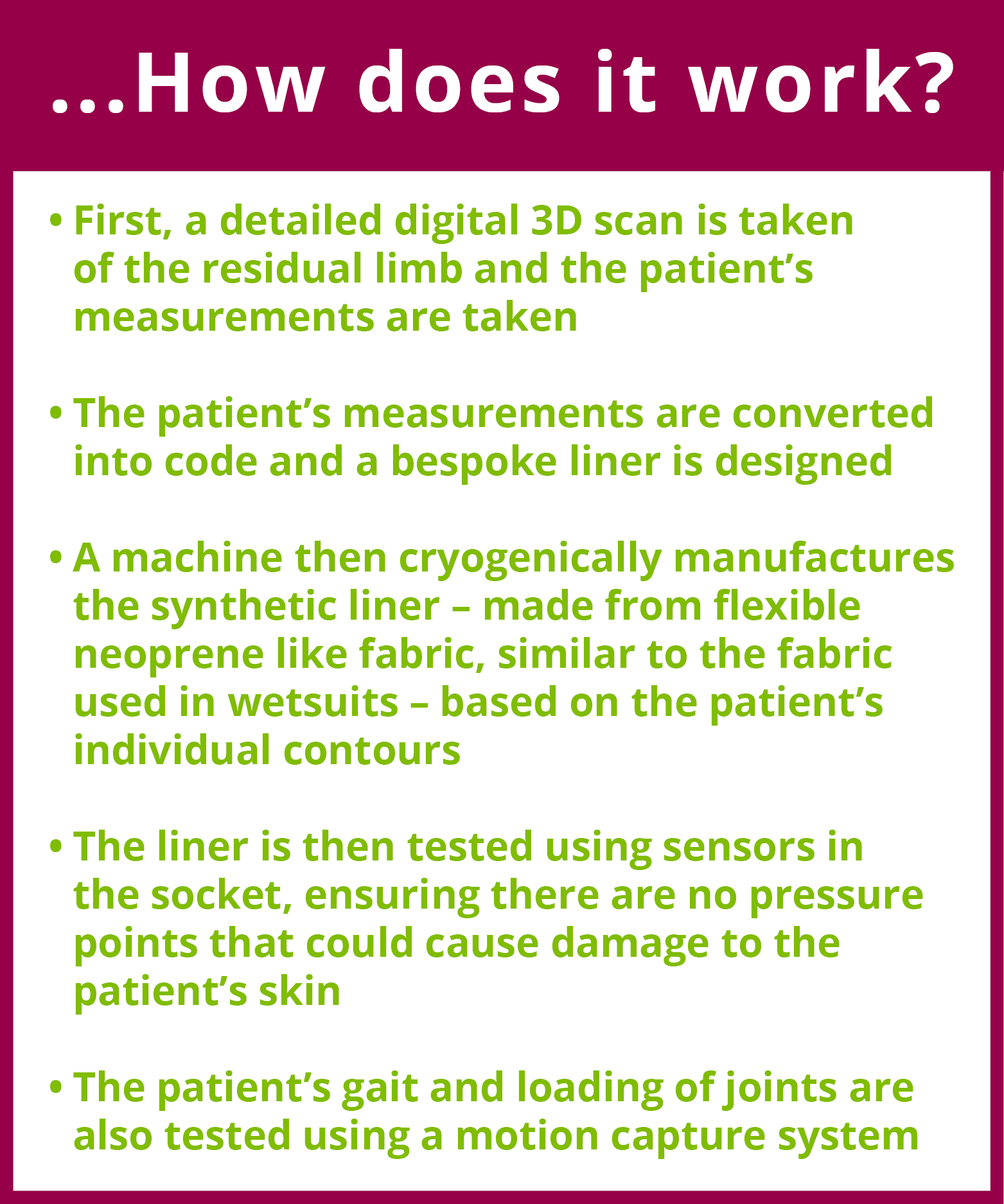

However, a group of scientists and engineers at Bath University are developing new made-to-measure synthetic liners to sit inside a prosthetic, with the aim of aiding the healing process. John is assisting the university with their research, allowing them to test out the liners in his own prosthetic, which he currently lines using three layers of socks and a silicone liner.

Dr Vimal Dhoka, a design engineer for the project, says that personalised products meet the precise and individual needs of the patient, meaning that the product fits better than standard liners and can assist with the healing process following an amputation.

Dr Dohka added: "They [the patient] can move around better, they don't have the issues you have with current products which require changing continuously or, in John's case, requires a silicone liner and a number of socks."

Dr Elena Seminati, another researcher involved in the project, adds that the made-to-measure liner will help John to have a better life, a normal life.

One of the main advantages of using the new slip for John, he says, is the speed in which he will be able to put his prosthetic leg on during an emergency, as he worries about being able to flea easily if there was, for instance, a fire in the middle of the night.

John is now looking forward to moving on with his life, he said: “[The new made-to-measure liner] going to make "a massive difference, I'll be happier. As far as I'm concerned, it'll make life easier."

"If I've got to be a guinea pig, I'll be a guinea pig, I don't mind," he says. "Because I always look at life - somebody's worse off than me… there are people a lot worse off than me who have lost limbs.”

Richard Edwards, a Partner within the Personal Injury team here at Potter Rees Dolan, comments:

This sounds like a very promising project. Socket comfort is absolutely vital to facilitating good and regular usage of prosthetic equipment. That makes it essential to helping amputees to get back to enjoying as full a life as possible following amputation surgery. I look forward to reading more about this project as the product is developed further.

Richard Edwards is a Partner in the Personal Injury team at Potter Rees Dolan who specialises in Brain, Orthopaedic and Amputation injuries, as well as high value Occupational Stress stress claims. Should you have any queries regarding Personal Injury, Amputation Claims or indeed any other aspect of this article and wish to speak to Richard, or any other member of the team, please contact us on 0161 237 5888 or email Richard directly.